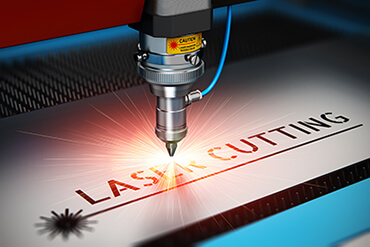

LASER CUTTING SERVICES

The term “LASER” stands for Light Amplification by Stimulated Emission of Radiation.

Cutting is performed by directing the energy of a high-power laser at the metal to be cut. The beam then melts or burns the material with precision accuracy.

Generation of the beam involves stimulating a lasing material by electrical discharges within a sealed container. The beam created as a result of the stimulation is reflected internally by means of a partial mirror, until it achieves sufficient energy to escape as a stream of focussed light through a lens.

The most common type of industrially used lasing material is Carbon Dioxide. Carbon Dioxide lasers can cut many materials including mild steel, aluminium, stainless steel, titanium, paper, wax, plastics, wood, and fabrics.

LASER PROCESSING BENEFITS

- The high energy focused heat source provides for accuracy up to ± 0.1 mm

- Little thermal effect and no mechanical distortion.

- Hardened steels can be cut with minimal effect on temper plated or coated steel can be cut with minor edge damage.

- Very thin materials can be cut without the problems of tool clearance normally required.

- Lasers can cut materials in intricate shapes normally found impossible using conventional manufacturing techniques.

- High degree of control, providing unlimited profiling capability due to the absence of a cutting edge.

- Kerf compensation for accurate cutting of mating components.

Flatbed Laser Cutting

Laser World can precision cut a variety of metals from stainless steel, mild and high tensile steels to various alloys. Our state of the art high-speed cutting equipment can handle up to 1500mm x 3000mm plates.

Tube Laser Cutting

Laser World’s flexible Tube Laser’s equipped with a tilting head that allows 3D cut processing on all sections (open and special profiles). Its efficient loading system delivers unmatched productivity.

CNC Press Brake Folding

The punch of a press brake uses a lot of force, which means it is geared for heavier and thicker sheets of metal. It still offers precision and accuracy, but it just does so with much more substantial sheets of metal.